Optimas to open cold-forming plant in Nuevo León

MONTERREY, NL – Optimas Solutions, an industrial manufacturer/distributor and global service provider, will open a cold forming plant in Monterrey, Nuevo Leon, in the second half of 2024.

With this Mexico production facility the company seeks to complement manufacturing operations in Wood Dale, Illinois, and Droitwich Spa in the United Kingdom. The initiative will also continue the company’s efforts to minimize supply chain risk.

The new facility will also complement the 32,400-square-foot distribution center that the company has operated since 2021 in the municipality of Apodaca. Optimas did not disclose the amount of investment it will allocate to the new plant.

“More than ever, the availability of resources has given way to accessibility in the form of regionalization,” said Daniel Harms, CEO for the Americas, in unveiling this project. “Our expanding location strategy allows us to be more agile with our manufacturing and sourcing capabilities for industrial customers and suppliers.”

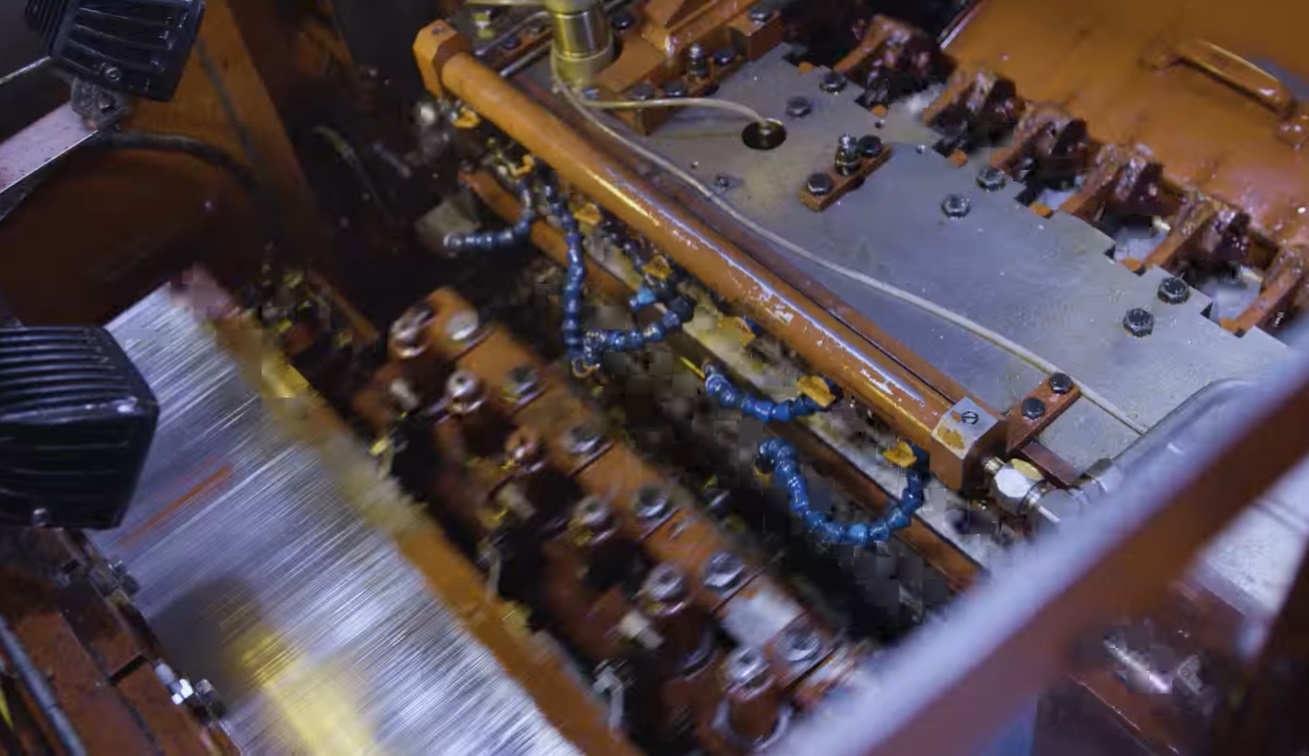

“We took great care to design our Mexico facility to mirror our manufacturing capabilities at Wood Dale so that they can compete with each other effectively,” said Ricardo Alonzo Rodriguez, vice president and general manager of Optimas in Mexico. “This ensures that customers and suppliers have access to the same engineering, tooling, manufacturing and quality processes regardless of where we produce fasteners.”

Optimas is one of the few companies with in-house cold forming in the U.S., U.K. and now Mexico, which complements the global distribution of fasteners and procurement of Class C parts. By working with a full-service distributor that is also a manufacturer, industrial producers can leverage multiple procurement avenues and have the support of automated replenishment services, predictive analytics, engineering creativity, a certified quality management system and existing carrier relationships that ensure reliable delivery. .

“The ability to have dual sourcing adds significant strength to a customer’s procurement strategies because you can combine the breadth and depth of sourcing with the ability to manufacture more complex parts locally,” Harms said. “As demand fluctuations occur at an ever-increasing rate, procurement specialists depend on partners who are flexible to meet production requirements.”